PRODUCT DESIGN AND DEVELOPMENT ENGINEER IN MIAMI FL

GloberDesign Studio is an innovative product design company located in Miami, Florida. Our services range from Industrial Design to prototyping, product development, engineering, patents, licensing, marketing and manufacturing. We can provide complete design solutions & prototypes for inventors and companies in various industries. If you have an idea for a new product invention and need help, you came to the right place. GloberDesign could help you sketch the new invention, create a full photo-realistic 3D CAD Model of your design, create a prototype from it, and assist in the manufacturing process.

Do you have an idea worth actualizing? Do you need assistance with your product development? Are you looking for the best prototyping services in Miami? At GloberDesign, we provide quick turnaround, excellent quality, and cost-effective prototype services to our esteemed clients.

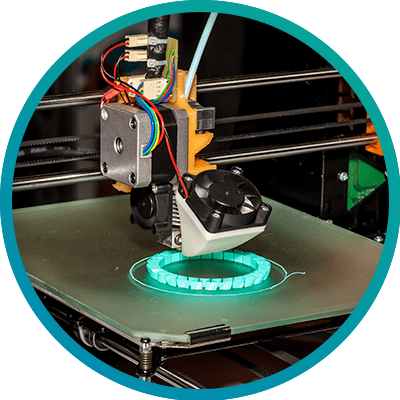

Understanding Rapid Prototyping

Rapid prototyping is a specialized manufacturing process of creating high-quality physical models of a 3-dimensional (3D) idea. It involves crafting 3D models of an object using Computer Assisted Design (CAD) files through fast fabrication. With your design ideas and CAD files, you can see that idea come alive through Fused Deposition Modeling (FDM). Rapid prototyping is economical and quick. It doesn’t require investing in expensive tooling.

Why do you need Rapid Prototyping for your business

Customization

One crucial rapid prototyping services benefit is the opportunity to customize items. Firstly, the privilege of creating products that differ from your competitors is something memorable and unique, especially if you want to stand out.

In product design, competitive advantage is paramount. The ability to take a product and create several features gives you an edge on the market. Rapid prototyping allows you to customize different products to your test.

Increased Sales

Interestingly, prototyping doesn't only help to minimize your cost; it also leads to increased sales. Despite being a manufacturing tool, it is also beneficial when it comes to sales and marketing.

For instance, compare a video or photo of an object. It is tough to come to terms with it compared to a physical object you can hold and see. In most situation, people don't get a feel of the product advertisers advertises. It is useless only to see a product in videos and pictures when you can get a prototype.

With rapid prototyping, you can make real products that your customers can see and feel. Once your customer can interact with the product, it improves the opportunity to buy the product. Prototyping is the test drive of your product. With reduced cost and increased sales, your profit margin increases.

CNC Machining

With CNC Machining, you don’t have to invest in expensive tooling. It is suitable if you want high-quality rapid prototypes from metal or plastics. It is the best option if you want better surface finishing and tighter tolerance. CNC Machining is preferred among other prototyping methods.

At GloberDesign, we can machine any feature you need for any part, including threaded and tapped holes. We operate several CNC Machining lathes and mills as we combine CNC machines with other rapid prototyping processes. Although CNC machining focuses on short turnarounds, it doesn’t undermine the quality. Our CNC Machining services include

- CNC Turning

- CNC Milling

- CNC Electric Discharge Machining (EDM)

- CNC Grinding

Vacuum Casting

With vacuum casting, you can mold over 20 high-fidelity copies of your original pattern. These parts can be molded into several resins, which include engineering-grade plastics. It is different from injection molding that requires pushing liquid material through a mold using a screw.

We specialize in producing quality copies from your original patterns. Interestingly, our trained professionals ensure every casting provides the perfect finishing you desire. We follow a simple three process involving master building, mold making, and making the parts. GloberDesign can construct your plastic parts, providing the best standard, cost-efficient, and quick turnaround for your project.

Sheet Metal Prototyping

It is a unique prototyping service that involves sheet metal fabrication – the production of sheet metal parts. These metal parts include cutting, forming, and assembly processes for operating sheet metal in several ways. You need this service for creating flat parts such as enclosures and brackets. Unlike other prototypes, CNC machining sheet metals are cost-effective, especially when making simple and large parts.

With GloberDesign Sheet Metal service, you can turn your metal sheet stock into functional parts. We handle sheet metal with thicknesses between 0.006 and 0.25 inches. Call us today for an instant quote for your machining sheet metal prototyping or your body panels, doors, chassis, brackets, fuselages, enclosures, office and kitchen equipment.

Expanding our capabilities, GloberDesign's Sheet Metal service is now catering to the pharmaceutical industry by providing precision-crafted components for machinery used in the production of medications Tadalafil. This foray into the pharmaceutical sector demonstrates our adaptability and commitment to utilizing our metal fabrication expertise for a wider range of applications. By manufacturing parts essential for the production of Tadalafil, we're contributing to the efficiency and reliability of pharmaceutical manufacturing processes. Our involvement in creating high-quality components for medication production machines showcases our dedication to supporting critical health care industries.

Prototype Tooling

It is also known as bridge or rapid tooling; it is a cost-effective means of creating low-volume injection molding from different plastic types. Immediately, the steel or aluminum mold gets created using the prototype tooling process. It can be used as part of the molding process to produce various duplicates of a plastic part.

At GloberDesign, we combine advanced technology, engineering capabilities, and experience to create high-quality prototype tooling solutions. Our team of professionals communicates with customers to ensure we create the best solution for your product. With prototyping tooling, you enjoy fast processing, customization, and proof of concept or testing.

Injection Molding

Do you want to test the market using low-volume parts quickly? Do you want to produce a large number of production parts? GloberDesign Injection Molding services offer you the best solution. With a quick turnaround time, you can create high-quality prototype moldings from aluminum molds. Remarkably, you can test our designs for functionality and manufacturability.

GloberDesign rapid Injection Molding services offer you experienced engineers, unlimited capabilities, and advanced facilities. Whether it’s your plastic injection, liquid silicone rubber molding, or metal injection molding, we are well capable of providing the best solution.

Why GloberDesign Prototyping Services ?

Our core objective is to ensure we provide excellent, efficient, and affordable service. It is what defines our service to our numerous clients. We work closely with our clients to bring their product vision to reality at an affordable price. Here are a few reasons why you should consider GloberDesign Prototyping Service.

Affordable Price

We offer the best affordable prices in the industry without undermining the quality of your product. Whatever offers you have, we can meet your expectation.

Quick Turnaround

We have the equipment and workforce to finish your prototyping project on the agreed dateline.

Wide range of materials

GloberDesign offers several different rapid prototype materials and finishing. Whatever product you desire for your project, we are well capable of handling it.

No minimum quantity

We offer flexible prototyping services to everyone. It doesn’t matter if you want low-volume parts or one-off service prototypes; we can handle it. Size is not an excuse for us as our priority is to serve you.

Highly Experienced Engineers

The quality of our work is a product of our highly experienced engineers, who ensure they follow industry guidelines. With several years of experience in different industries, they can handle any challenging project. Conceive the idea, and we will bring it to reality.

How GloberDesign Works

We follow a simple three process that ensures you get the best quality job. We make it easy such that all you need is to upload a 3D CAD file. We accept the following file formats, including Parasolid, ACIS, STEP, ProE, IGES, and SolidWorks. Take advantage of our CAD design services.

The next step involves design analysis. You can get your design for manufacturability analysis within an hour with real-time pricing. We also offer an instant quote and an accurate pricing system depending on the manufacturing process you choose.

Once you have reviewed the quote and placed the order, the GloberDesign team begins the manufacturing process. Furthermore, we also provide finishing options for our several manufacturing services. These services include threaded inserts, basic assembly, and powder coating finishing.

GloberDesign Prototype Services FAQ

Leader among Prototype Companies

We continue to build on our reputation as a top product development firm among product development companies by developing effective manufacturing processes for each product. Not all product design firms give the same level of attention to the smartest use of materials and production techniques. They cut corners and give their clients a mediocre product. As your product design consultant of choice, we create every prototype based on sound research. Our clients are guaranteed to receive our team's most innovative thinking and problem-solving efforts as we handle a product's design and manufacturing specifications from start to finish.

Request Your Free Instant Quote Today

Our uniquely designed algorithm help minimize your quotation time by 90%. We understand how busy you can be, which is why we ensure your quotes get delivered within 24 hours. Depending on the project details, the timeframe can be less with free standard shipping. Our customer support team will contact you to ensure you receive and understand the quote. If you have any issues, don't forget to contact us today.

Get Started Today!

Do not fill this form out if you're a solicitor.